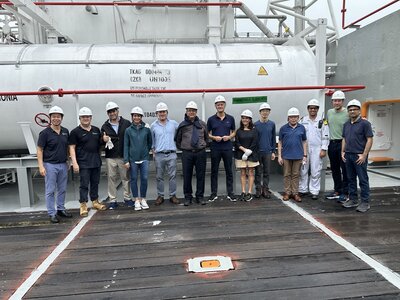

Recently, whilst in Singapore for Board meetings, a group of UK Club Directors and Managers visited the Fortescue Green Pioneer at the Singapore Anchorage. The tour, led by Mr. Andrew Hoare, head of Green Shipping at Fortescue, and supported by the crew, provided an insightful look at this pioneering vessel. The Green Pioneer has become a symbol of innovation and progress in the maritime industry, particularly in the use of ammonia as a ship's fuel. Although still a prototype, it is the first ocean-going ammonia-powered supply vessel.

During the Club’s visit, the vessel’s engines were operating on diesel oil, but the crew explained how the vessel has been retrofitted to use ammonia in her engines. The conversion process for the Fortescue Green Pioneer involved retrofitting two of the vessel’s four engines to run on ammonia. This work, conducted at Seatrium’s Benoi yard, included integrating a sophisticated gas fuel delivery system, along with essential safety systems and infrastructure. The remaining two engines remain on conventional fuel, providing operational flexibility. Mr. Hoare described the meticulous safety protocols and specialized crew training that were necessary for handling ammonia as a fuel. This included advanced workshops on risk mitigation, emergency response drills, and the use of specialized personal protective equipment, such as chemical protection suits and portable gas detectors, to ensure crew safety in case of accidental ammonia exposure.

The Green Pioneer is equipped with several advanced systems to ensure the safe and efficient use of ammonia as a fuel. Visitors were immediately struck by the ship’s deck layout, which houses specialised equipment essential for its ammonia-burning capability. At the bunker station, ammonia is loaded onto the vessel with meticulous monitoring due to its highly toxic nature. The Chief Engineer explained that after connecting the bunker hose and performing safety checks, the crew uses a remote panel from the bridge to control the valves. Gauges and sensors continuously monitor pressure, temperature, and flow rates to detect any leaks.

The Scrubber System is essential for neutralizing any residual ammonia. It uses a citric acid solution that reacts with the ammonia residue, turning it non-toxic before it is released from the mast. The nitrogen generation system extracts nitrogen from the air using two onboard generators. The nitrogen is then compressed and stored in tanks before being used to purge the ship’s systems of ammonia residues, ensuring that any remaining ammonia is safely removed.

The ammonia tank, situated on the vessel’s main deck, is designed to be exceptionally robust. It can be filled with ammonia at -33°C, and the liquid gradually rises to ambient temperature once inside. In the fuel preparation room, ammonia is transformed from liquid to gas using residual heat from the engine’s cooling system. This room is equipped with numerous connections, valves, and instrumentation, and is isolated while the ship operates on ammonia. The double-door airlock system and compartmentalized construction provide an additional layer of safety.

Ammonia is circulated throughout the ship via a double layered protection system. Sensors embedded within these layers continuously

monitor for leaks, ensuring any issues are quickly detected and resolved. In the Engine Control Room, engineers can oversee and regulate the flow of ammonia to the engines, which have been modified from their original design to operate on ammonia. The Engine Room contains these retrofitted engines, which have undergone extensive testing and calibration by experts.

The ship’s certification by DNV and its recognition by the Singapore Registry of Ships (SRS) validate the technology and fuel systems, setting a precedent for future ammonia-fuelled vessels. Fortescue’s partnership with DNV, which performed a rigorous technology qualification process, was instrumental in bringing this vision to life. This collaboration, alongside support from Maritime Port Authority of Singapore (MPA), ensured that the ammonia systems met stringent safety standards and could operate in the demanding maritime environment.

By demonstrating the viability of ammonia as a marine fuel, the Fortescue Green Pioneer plays a crucial role in global efforts to reduce carbon emissions from shipping. Although the Fortescue Green Pioneer is a prototype, it marks an important milestone for ammonia-fuelled vessels. However, several challenges remain. The entire deck space of the vessel has been utilized for various modules such as the fuel tank, scrubber units, nitrogen generation plants, and post-combustion systems. Consequently, the ship is not ready for commercial operations and serves as a model to showcase the development of ammonia-fuelled vessels. Key operational experience for using ammonia as fuel is still needed, as the vessel is not running on ammonia after the trial runs. Further developments are required to reduce emissions such as ammonia slip and N2O, a highly potent greenhouse gas. Nevertheless, the Fortescue Green Pioneer stands as a testament to the potential of ammonia as a green fuel and the engineering prowess required to make it viable for maritime use.

The UK Club is committed to supporting its Members in their transition to alternative fuels and technologies, whether that be ammonia or one of the other new fuels - please see the UK Club's article outlining the various transitional fuels and tomorrow's zero emission options available. The UK Club is also committed to ensuring that its loss prevention, underwriting and claims handling services continue to evolve to reflect the emerging needs and requirements of these technologies. Further details are set out in the Club's Sustainability Report and on the Sustainability pages of the Club's website.

For further information, please contact Ansuman Ghosh, Director of Risk Assessment, Patrick Ryan, Sustainability Director, or your usual Club contact.