1. The three factors that can lead to an accident

(environment, hardware, people)

The operation of ships is constantly becoming more advanced because of the use of the latest software and hardware. Despite this progress, we are still seeing many accidents that are basically the same as the accidents that occurred 50 or even 100 years ago. An analysis of the causes reveals that negligence and carelessness that have not changed in the past have been repeated.

The behavior of people is obviously a major factor involving accidents, as these reports have stated before. Operating ships requires at all times a “human metabolism” encompassing the crews of ships, the onshore management of ships (senior executives) and oversight by regulatory agencies for shipping. Over time, the people involved in this metabolism are replaced with new generations of personnel. Unfortunately, sufficient information often is not passed on to the next generation. For example, the new people may not receive information and precautions about past accidents, how to deal with causes, and implement preventive measures.

Why do accidents happen? The answer requires a close look at the three primary factors affecting the operation of ships: (1) Environment, (2) Hardware and (3) People. The environment includes the weather, sea conditions, the route and congestion of areas along the route. Risk factors involving the environment are always present. Hardware is the ship and includes risk involving maintenance, the use of the ship’s equipment and other items. People are both the crew on the ship and the onshore management team.

Since the environment and hardware are always the basic components of any voyage, the people involved must be able to skillfully handle these two factors. In other words, people have an obligation to minimize vulnerability to risk factors concerning the environment and hardware.

It may not be the right word, but I think the environment and hardware can be controlled to some extent by the crew and management. For the environment, storms and dangerous areas can be avoided by preparing a suitable passage plan. In addition, the risk of a collision with another ship can be reduced by identifying regions where there are many ships. For hardware, risk can be minimized by properly maintaining and operating the ship and its equipment.

Earlier, I stated that people are often neglecting to pass on lessons learned from accidents to the next generation. A safety management system that uses documents is needed to be certain that knowledge gained from accidents and proper responses to accidents are not forgotten. Furthermore, all ships on international routes are required to use a safety management system that complies with the International Safety Management (ISM) Code.

2. Learning from accidents of the past

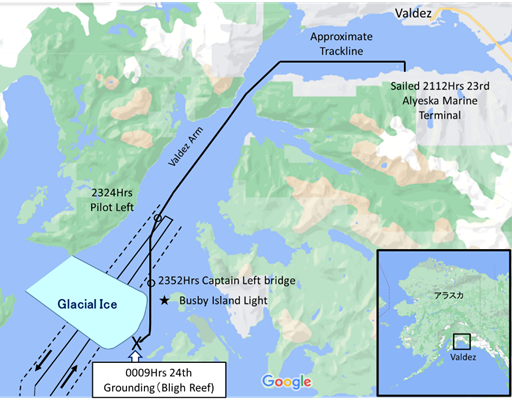

On March 24, 1989, the VLCC Exxon Valdez ran aground in Prince William Sound near Valdez, Alaska. The vessel spilled approximately 41,000 kiloliters of crude oil that soiled about 2,400 kilometers of coastline. Removal of the oil required expenditures of $2 billion.

Let’s examine the direct causes of this accident from the standpoint of the three primary factors. The environment forced the ship off its course in order to avoid floating ice in the channel. At that time, the width of the passable channel was less than one mile (1,852 meters). The Exxon Valdez was using the same route as other ships had in order to go around the ice. As a result, the National Transportation Safety Board (NTSB) stated that the ship’s course was reasonable.

Diagram : Location of the grounding of the Exxon Valdez

(Source: NTSB/MAR-90/04)

There was no problem with hardware regarding a breakdown or malfunction of the ship’s instruments and other equipment. However, there was a problem concerning how the ship was steered. The third officer, who was on duty at that time, intended to move the rudder but did not confirm that the rudder’s position had changed.

Numerous problems involving people played a role in this accident. First, the third officer, who was navigating the ship, made a large number of mistakes, such as failure to monitor and confirm the ship’s position and the use of an improper steering method, due to fatigue. However, the NTSB concluded that the ship’s owner was responsible for creating an environment that caused the third officer’s fatigue. The investigation also revealed that the ship’s owner had a personnel management system that encouraged people to work long hours. Consequently, the grounding of the Exxon Valdez was caused by the inability of people to adapt to the environment and properly use the hardware.

Many unsafe acts and unsafe conditions contributed to this accident. Preventing accidents of this type therefore requires minimizing and breaking the error chain.

3. The role of onshore management in ship operations

Management (company executives and onshore ship management personnel) must support ships and their crews as much as possible in an appropriate manner.

The business operations of a company that operates ships will be successful only if the ship, which can be viewed as a tool for accomplishing a goal, is used skillfully. Management is fully responsible for the safety management of ships and must not rely entirely on the ship’s master and chief engineer who are responsible for the operation of the ship. As stated in the ISM Code, everyone involved must be aware that onshore and ship personnel are a single, unified team.

When there is a management team with a strong sense of responsibility, responses to marine accidents will be different and actions can be taken quickly to contain damage and end the emergency. Individuals who are responsible for the day-to-day management of ships must also be aware of their responsibilities in the event of an accident.

4. Key points for safe navigation

The fundamental premise for safe navigation is onshore ship management that is able to keep track on a real-time basis of events within the management organization and on board ships.

This premise is the same as the thinking behind situational awareness for bridge resource management (BRM) and bridge team management (BTM). Here, situational awareness regarding ship management means the constant awareness of whether or not the ship is operating in compliance with the standards and rules of the ship and the organization to which the ship belongs. One more critical point is the need to realize when a situation occurs that causes a ship to no longer comply with a standard or rule and to make improvements promptly.

The operation of ships must comply with the SOLAS Convention (the International Convention for the Safety of Life at Sea, which was passed in 1914) and other international rules. In addition, safe navigation extends to internal regulations, ship/shore safety management systems established by ship management companies, and other frameworks. Furthermore, based on this situational awareness, vulnerability to risks must be minimized by improving procedures for performing tasks and conducting drills and education programs as needed.

In summary, the mission of onshore management is to provide as much support as possible to ships, which are the front line of activities for safe navigation. Safe and sound navigation is possible only when this type of appropriate and effective support framework is in place.

Source

This report was prepared by using an article titled “Safe and sound maritime transportation can be established with the support of the ship by onshore management” which is an interview with the author in Kaiun (The shipping, May 2023/No. 1148), which a periodical issued by The Japan Shipping Exchange, Inc.