Best practices for the carriage of soya bean: Managing risks and avoiding claims

Introduction

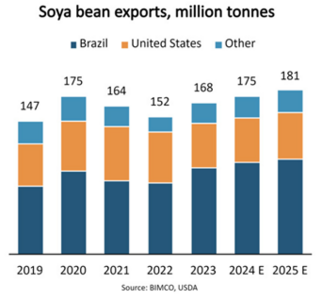

The export of soya beans from Brazil to China has shown significant growth in recent years. In May 2024, BIMCO reported that global soya bean exports are expected to grow by 8% until 2025. This trade growth comes with greater risks during transportation, especially related to cargo damage and associated claims. These claims typically occur annually, coinciding with the soya bean harvest cycle.

The impact of climate change, such as unseasonal rains, raises the inherent moisture content of the cargo and exacerbates these risks. To address these challenges and ensure the safe delivery of the cargo, this article outlines best practices for transporting soya beans. While it focuses on the soya bean trade from South America to the Far East, the key guidelines also apply to shipments of other grains and oilseeds in general.

Background

The United States and Brazil are two of the world’s largest producers and exporters of soya beans.

China, one of the largest importers of soya beans, has increasingly turned to Brazil as its primary supplier, particularly amid deteriorating trade relations with the United States.

According to the Club’s local correspondent in Brazil (Proinde), the 2024/25 soya bean season is expected to reach record-breaking levels.

The Brazilian soya bean exports typically accelerate in February as the new harvest begins to arrive at ports, building to a peak in March/April and declining towards the end of the second quarter of the year.

A typical voyage from Brazil to China (via the Cape of Good Hope) takes around 35 to 40 days. In contrast, the United States, the second-largest soya bean exporter, ships a significant share of its crops from ports in the Gulf of Mexico to East Asia via the Panama Canal, benefiting from a well-established transport infrastructure that minimises problems with soya bean transport.

However, in Brazil, the transport infrastructure has not kept pace with the rapid expansion of farming regions, resulting in longer delays, congestion during bad weather and extended transportation times for barged soya beans. Furthermore, differing standards between Brazil and China can create confusion when determining if a cargo has deteriorated, complicating the handling of claims.

In June 2023, Proinde reported that the Brazilian Ministry of Agriculture, Livestock and Supply (MAPA) aimed to revise its technical regulation to align it with national grading standards adopted by other major global oilseed players, notably China and the United States. One proposed change was to lower the moisture content limit from 14% to 13%. However, this proposal faced opposition from grain producers, leading to a stalemate in discussions.

Soya bean cargo is highly susceptible to self-heating due to its inherent moisture and oil content. Prolonged storage or extended transport periods can lead to significant deterioration of the cargo. The main signs of damage associated with soya bean cargo claims include discolouration, decomposition, foul odour, mould growth, self-heating and caking caused by excessive moisture content.

On 15 July 2024, Proinde reported that severe flooding in Rio Grande do Sul, a major grain-producing state, was expected to cause a 4.7% decrease in the 2023/24 soya bean harvest compared to the previous 2022/23 season. On the same day, the Club’s local correspondent in China (Oasis) issued a circular regarding the surge of heat damage claims for Brazilian soya beans at Chinese ports.

Loss Prevention Advice

To mitigate the risks associated with the carriage of soya beans, the following key steps can be taken:

Before loading:

- Ensure that cargo holds are prepared to ‘grain clean’ standards. The holds are required to be dry, clean and free from any odour or contaminants that could potentially spoil the shipment.

- Check the weathertightness of hatch covers, preferably by the ultrasonic test method, and keep records of these tests.

- Ensure that all the ballast tanks adjacent to the cargo holds are pressure tested to ascertain watertight integrity.

- Examine the condition of cargo hold ventilators, access hatches, manhole covers, and air and sounding pipes, and ensure that these are properly maintained with no signs of leakage.

- Test the cargo holds’ bilge suction and check for any backflow through the non-return valve. Also, test the cargo hold water ingress alarms and dewatering system (if fitted) for proper functioning.

- Ensure that the bunker tanks adjacent to the cargo spaces that require heating are identified and that measures agreed upon with the ship’s Chief Engineer to ensure that fuel oil is heated to the minimum pumpable temperature are implemented. Bunker planning should be done in advance and steam supply valves should be closed for empty bunker tanks.

- Obtain a grain and oilseeds quality certificate [1] sufficiently in advance of loading to ascertain the grade and oil/moisture content of the cargo intended to be loaded. This would assist with a timely response in cases where the cargo could pose potential issues during the voyage due to its inherent condition.

- Consider appointing a surveyor to conduct a preloading survey of the cargo.

- Obtain clear instructions on cargo ventilation from the shippers/fumigators/charterers and seek timely clarifications if the instructions are contradictory. Forward any instructions from fumigators to charterers and ask for confirmation that owners should comply. If there are any concerns, members should contact the Club for advice.

During loading:

- During the loading process, it is important to visually inspect the cargo regularly to ensure that it is in apparent good order and condition. Check the grain colour and odour for signs of infestation and contamination. Take date- and time-stamped photographs to document the condition of the cargo.

- Ensure cargo temperature is monitored at regular intervals using a calibrated probe. If elevated temperature or damaged cargo is detected, notify the Club. The Club will assist in appointing surveyors and experts to carry out cargo sampling and testing. It is recommended that the cargo is representatively sampled according to the sampling methods of the Federation of Oils, Seeds & Fats Associations Ltd (FOSFA) for oilseeds.

- Ensure that the loading sequence is recorded in all circumstances and that it complies with the stowage, trimming and stability requirements outlined in the International Grain Code.

- Ensure that the hatch covers are kept closed during periods of precipitation. The weather forecasts should be monitored closely. If cargo is found to be wetted, photographs of ineffectively covered cargo prior to loading, as well as any wetted loading equipment, should be obtained. A letter of protest (LOP) should be issued by the Master and any wetted cargo rejected. Any delays to the loading process should be detailed in the logbook and LOP.

- In addition to the above-mentioned guidelines, members with ships loading soya beans in Brazil are recommended to refer to Proinde’s practical guidance on loading soya beans in Brazil.

During voyage:

- Soya beans, like other grain and oilseed cargoes, are usually fumigated in transit to prevent insect infestation. The fumigator should provide detailed documentation, including the type of fumigant, method of application, dosage, exposure duration and method of residue disposal. The commonly used fumigants are aluminium or magnesium phosphides, which come in pellet form. These pellets are spread uniformly on the cargo or inserted beneath the layers using retrievable sleeves. It is important to comply with IMO recommendations on the safe use of pesticides in ships applicable to the fumigation of cargo holds (MSC.1/Circ.1264, as amended by MSC.1/Circ.1396).

- Ensure that the cargo ventilation is conducted with due consideration to the best seamanship practices, fumigator’s instructions and voyage orders. It is recommended to assess the situation every four to six hours, since changes in weather and sea conditions may affect when ventilation should be undertaken.

- The decision to ventilate should be based on either the ‘Three Degree Rule’ or ‘Dew Point Rule’ when the weather/sea conditions permit. For hygroscopic cargoes such as soya beans, the ‘Three Degree Rule’ is normally recommended. Alternatively, the control of moisture in the cargo holds can be done by using dehumidifiers.

- Ensure that regular checks of ambient and cargo temperatures are conducted throughout the voyage, and maintain a detailed ventilation log. In addition to recording ventilation periods, this log should also include reasons for not ventilating, such as bad weather, fumigation, etc.

- When carrying heat-sensitive cargoes such as soya beans, it is recommended to isolate the electrical supply leading to the cargo holds.

- There have been several incidents of soya bean cargo damage due to bunker tank heating. Ensure that temperature records for bunker tanks during the voyage are duly maintained.

At discharge port:

- Ensure that all relevant parties are invited to attend the vessel when the hatch covers are opened to inspect the cargo surface for any signs of damage or condensation. Record the condition of the cargo with associated date- and time-stamped photographs.

- If the vessel experiences a delay, notify the Club, issue an LOP and put the charterers on notice. If the delay may result in cargo damage, the Club will appoint competent surveyors to witness the hatch opening and to check the appearance and temperature of the cargo.

- It is recommended that representative samples of the cargo are taken following the same FOSFA guidelines that were employed when loading. Segregate any damaged cargo to minimise claims.

- Ensure that the subsurface temperatures are regularly monitored, using calibrated probes to assess signs of cargo heating. If necessary, partially open hatch covers to improve air circulation, but only under safe conditions.

- The cargo should only be discharged in favourable weather conditions and the hatch covers of all non-working holds should remain shut. If rain is imminent, cargo operations should be suspended and the working hatches promptly closed.

- During discharge, if any cargo damage is observed, notify the Club. The Club will assist in appointing a suitable and experienced local surveyor and/or expert. The pattern, type and extent of the damage should be documented to assist those who may be appointed by the Club to investigate the cause.

- Ensure photographs are taken at regular intervals throughout the discharge operation. Additionally, maintain written records throughout, including remarks on how the cargo was handled and details of spillages (if any).

Conclusion

By following the guidelines mentioned above, members can significantly reduce the risk of damage to soya bean cargoes during loading, carriage and discharging. However, external factors such as political shifts, economic conditions and varying international standards can still pose challenges. In such cases, thorough documentation and adherence to established protocols are essential for defending against claims and ensuring successful delivery.

To further protect against claims, careful attention should be paid to the drafting of charter party clauses, particularly those related to the fumigation and cleaning of cargo holds. Additionally, it is crucial to collect and retain key documentation such as bills of lading, mate’s receipts, grain quality certificates, logbook extracts, survey reports, and cargo temperature and ventilation records.

For more safety advice and guidance, check out our Ask an Expert video with CWA below.

----

[1] Grains and oilseeds, such as soya beans, are regulated by the International Code for the Safe Carriage of Grain in Bulk (International Grain Code) instead of the International Maritime Solid Bulk Cargoes (IMSBC) Code. However, processed products such as soybean meal (SBM) would fall under the individual schedule of SEEDCAKE of the IMSBC Code, whereby it would be the shipper’s obligation to provide a cargo declaration form per section 4.2 of the Code.